- Introduction: What is the

5-S? - A

Brief history of the 5s system - Twelve

types of resistance to the 5S - Benefit

- Reference

Introduction: What is

the 5-S?

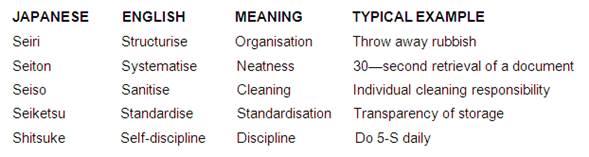

5-S stands for five Japanese words: Seiri, Seiton,

Seiso, Seiketsu and Shitsuke (Osada, 19911). The English

equivalent, their meanings and typical examples are shown in the

following table:

Japanese factories are well-known for their cleanliness

and orderliness. This results from their ability to instil a

sense of responsibility and discipline into their workers,

particularly at the plant level. The logic behind the 5-S

practices is that organisation, neatness, cleanliness,

standardisation and discipline at the workplace are basic

requirements for producing high quality products and services,

with little or no waste, and with high productivity.Surprisingly,

this powerful quality tool has been unknown in the west. The

western world has just recently recognised the significance of

the 5-S practice, although there are indications that some

companies have included some aspects of the 5-S in their routines

without being aware of its existence as a formalized technique.

There are many examples of successful implementation of some

principles of the 5-S, especially in the service sector

organisations, such as fast food restaurants. supermarkets,

hotels, libraries, and leisure centres.

A Brief history of

the 5s system

A systematic approach to organizing, ordering, and

cleaning had its origins in post-World War II

Japan—probably in the mid 1950s. At the time, Japanese

manufacturing companies were forced to produce with very few

resources, so they developed a shopfloor method to make every

scrap count while wasting nothing.

Originally, there were only four activities in the

Japanese system. These activities, each beginning with the letter

S, were

1. Seiri (cleaning up),

2. Seiton (organizing),

3. Seiso (cleaning), and

4. Seiketsu (systematic

cleanliness).

Later, a fifth activity was added. Called Shitsuke

(discipline), it completed the S elements that are now known as

5S. (Fabrizio A. & Tapping, 2006 , pág. 2).

Twelve types of

resistance to the 5S

Any company introducing the 5S is likely to encounter

various kinds of resistance, whether from the shop-floor or

clerical staff. I group such resistance into the twelve types

shown in Figure 1-1:

Resistance 1. What"s so Great about Resistance 2. Why should I, the President, Resistance 3. Why Clean When it Just Gets Resistance 4. Implementing Organization and Resistance 5. Why concern ourselves with Resistance 6. We Already Implemented Resistance 7. My Filing System Resistance 8. We Did the 5S Years Resistance 9. 5S and Related Improvements Resistance10. We"re Too Busy to Spend Time Resistance 11. Who Are They to Tell Me What Resistance 12. We Don"t Need the 5S – |

Figure 1-1. Twelve Types of Resistance

to the 5S

Resistance 1. What"s so Great about Organization and

orderliness?

This direct resistance toward 5S implementation is like

asking "Why make such a fuss over something so obvious?" or

"You"re treating us like kids ordered to clean their rooms." But

the fact remains that 5S implementation is needed when the

factory or office is not neat & organized. This particular

resistance stems from the humiliation people feel when they think

they are being treated like children. Therefore, the key is to

eliminate such humiliation before implementing the 5S.

Resistance 2. Why should I, the President, Be 5S

Chairman?

More times than I care to recall, company presidents

have said something like: "You don"t really expect me to get

involved in something as trifling as Organization and

Orderliness?" Instead, they want to assign the 5S chairmanship to

the middle manager. "After all," they add, "I have more important

things to do – like manage the company"s sales and business

policies."

I would be the first to agree that sales and business

policies are important. However, believe it or not, the 5S are

even more important as a foundation of corporate strength.

Obviously, some presidents don"t believe this – but were

the company 5S foundation to be destroyed, they would soon find

out what I mean. Nor do many presidents understand how difficult

it can be to implement the simple 5S. 5S implementation requires

leadership, and top management just abandon its vain

preconceptions and get personally involved.

Resistance 3. Why Clean When it Just Gets Dirty

Again?

Factory people tend to accept dirtiness as an inevitable

condition in their workplace. They argue that cleaning it up

would do little good since it would soon get dirty again. When

employees are indifferent to making and maintaining improvements,

it is not surprising that defect rates remain high and

productivity low. Acceptance of unclean conditions in a workplace

must be eliminated.

Resistance 4. Implementing Organization and

Orderliness Will Not Boost Output.

This objection is heard most often in busy factories.

Usually, it is spouted by shop-floor people standing in a pigsty

asserting that "our job is to make things". Some workers –

and their managers – judge productivity by how much they

move and sweat. This is fine at the athletic club, but not in the

factory. In a factory motion is often a form of waste. Everyone

must learn the important difference between "moving" and

"working".

Resistance 5. Why concern ourselves with

Triviality?

The culprits here are typically middle managers such as

leaders of teams, sections, or departments. I"ve heard these

people say that dirt is a minor problem while standing on a

factory floor drenched with oil or covered with a thick layer of

machining chips.

Any manager who treats the 5S as trivial is really

trivializing productivity and efficient management activity.

After all, any manager who can stand on an oil-drenched floor and

call dirt a minor problem is someone who might absentmindedly

toss a cigarette butt onto that floor and cause a

fire.

Managers who fail to promote neatness and order end up

with a sloppy and undisciplined work force. For this reason, we

must eliminate managerial disregard for the 5S.

Resistance 6. We Already Implemented Organization and

Orderliness.

Some managers only consider the superficial and visible

aspects of the 5S. They think that rearranging things a little

and putting them into neat rows is all there is to it. Their

factories tend to undergo a "makeover" just prior to the company

president"s inspection tour – floors are swept, walls

painted, and objects lined up neatly. However, such orderliness

only scratches the surface of what the 5S are all

about.

When the unsuspecting president enters the made-over

factory, he is duly impressed and says something like "Wow, now I

call that clean!" Usually never seeing behind the veneer of

superficial Organization and Orderliness, he leaves the factory

with a false impression.

Resistance 7. My Filing System Is a Mess

– but I Know My Way Around It!

Some people are able to work around piles of papers and

files. In fact, the sheer volume of the mess reassures them of

their productivity.

I encounter people who actually get upset when I suggest

that they clear off their desks. They mutter something like

"Please leave me alone – I work better this way" and return

to the comfort of their mess. Such people tend to be loners who

avoid contact with others and like having a wall of books and

papers around them. Theirs is a different world from the one that

results from standardization and 5S implementation. The first

step in standardizing clerical operations is to open up such

private messes so that books and files are easily accessible to

anyone who needs them.

Resistance 8. We Did the 5S Years Ago.

This type of comment is heard most often from people who

think the 5S movement is a fad. If they attempted 5S

implementation once 20 years ago, they don"t see why they should

do it again.

The 5S are not a passing fashion. They actually are the

fertilizer on the field of making improvements. They are the

foundation of long-term corporate survival. People who don"t know

this should be informed; people who think they don"t need to know

it should get off their high horses. When I hear someone say they

did the 5S 20 years ago, I am tempted to ask, "Has it also been

20 years since you took a bath"?

Resistance 9. 5S and Related Improvements Are Just

for the Factory.

In some companies, while the manufacturing people

energetically implement the 5S and other improvement and

rationalization measures, the clerical and sales people assert

that such measures have nothing to do with their kind of work.

They do not realize that allowing documents and memos to litter

desktops is the same as allowing dirt and cutting debris to

litter factory floors. This is why 5S implementation must be a

company-wide program.

Resistance10. We"re Too Busy to Spend Time on

Organization and Orderliness.

In some workplaces, Organization and

Orderliness are the first things ignored when things get busy.

Soon we find jigs and tools left out, parts and materials piled

in inconvenient places, and oil and grime building up on the

machinery and floors. The excuse is always that "we"re too busy

for that." Are these people too busy to take showers and brush

their teeth? What they"re really saying is that they don"t want

to keep the place neat and clean, and this is their excuse. The

truth is that their excuse are no more valid than their attitude

toward cleanliness.Resistance 11. Who Are They to Tell Me What

to Do?

Most 5S implementations run into the human-relation

problems early on. Someone might understand how important the 5S

are but object to taking orders from the 5S promotion people.

Once human relations become tangles up, it takes a long time to

smooth them out. Consequently, it pays to form 5S promotion teams

with members skilled at applying the 5S to human

relations.

Resistance 12. We Don"t Need the 5S – We"re

Making Money, So Just Let Us Do Our Work!

It can be difficult to implement the 5S or other

improvement programs at companies that are currently profitable.

If you point out that it is more efficient to keep only one box

of parts on hand at each process, you will likely be countered

with something like "Yes, but we"re doing alright, and this is

the way we like to do it." Generally, such people fail to

recognize how many processes are involved in making a product.

Instead of emphasizing the productivity of individual processes,

we should look first at the overall production flow. Production

has a rhythm, and this rhythm gets upset when workers care only

about their individual processes. A poor rhythm has a negative

impact on inventory and conveyance management, which in the end

creates more waste, such as the extra time needed to find certain

items. By allowing operators to do things their way, we grant a

selfish kind of freedom that hurts everyone in the long

run.

These types of resistance occur at every factory in the

early stages of 5S implementation. If we ignore such resistance

and plow ahead with 5S implementation, the result will likely be

nothing more than superficial improvements. Instead, we must get

everyone to truly understand just how necessary the 5S are while

incorporating 5S implementation into ongoing improvement

activities. This is how to lay a solid foundation for overall

improvement. (Hirano, 1995, págs. 22-26).

Thorough implementation of the 5S affords many direct

and indirect benefits. What I call the essential benefits are

listed Figure 1-2

Figure 1-2. Benefits of the

5S.

Benefit

Benefit 1. Zero Changeovers Bring Product

Diversification

The trend toward product diversification accelerates

with each passing day. Companies that continue to practice

"shish-kebab production" are finding themselves unable to keep up

with this trend To remain competitive, they must reduce to zero

the extra time taken for retooling and other changeover

operations, increase the frequency of changeover, and become more

adaptive to product diversification.

The orderly arrangement of dies, jigs, and tools

eliminates a major form of waste ("searching"

waste).Clean equipment and a near workplace help raise

operational efficiency.Thorough implementation of the 5S"s makes workshops

simple and logical enough for observers to understand with

ease. Don"t use non-specified jigs for the sake of

convenience.

Benefit 2. Zero Defects Bring Higher

Quality

Defects result from many causes, including attaching the

wrong parts and using the wrong jig. Organization and Orderliness

prevent these kinds of errors. Further, keeping production

equipment clean reduces equipment-operation errors and enables

faster retooling. These and other 5S effects all add up to fewer

defects.

Defects are harder to discover when the workplace is

a mess.Taking things from and then returning them to

designated locations will help eliminate part and tool

selection errors.Clean equipment tends to operate normally and

without defects.A clean and well-organized workplace makes workers

more conscious of the way they are making things.Proper maintenance and storage of quality-assuring

inspections tools and measuring instruments is a prerequisite

for zero defects.

Benefit 3. Zero Waste Brings Lower

Costs

Factories and offices are virtual storehouses of waste.

In Japan, a television slogan states that people who spend a lot

of time talking on the telephone or carrying around to many

papers cannot get much work done. And I agree completely. Big

telephone talkers fail to implement Organization and Orderliness

o shorten their phone conversations. People burdened with too

many papers fail to implement Organization and Orderliness by

hung or dis carding unnecessary papers. Long telephone

conversations and armloads of papers are two forms of waste, and

too much waste can prevent us from getting any productive work

done. This applies to both factories and offices.

Eliminate too much "stand-by waste" in in-process

inventory and warehouse inventory.Eliminate too-much-w-carry waste" in handling

documents or other materials.Eliminate overly abundant (unneeded) storage places

(warehouses, shelves, cabinets, lockers, etc.).Eliminate "sand-by waste" in waiting for conveyance

equipment (pallets, Carts, forklifts, etc.).Eliminate waste arising from unneeded desk supplies

(too many pencils, erasers, etc.).Eliminate waste arising from unneeded allocation of

space and equipment.Eliminate wasteful motion in searching.

side-stepping. etc.Eliminate non-value-added actions (picking up,

putting down, counting. carrying. etc.).

Benefit 4. Zero Delays Bring Reliable

Deliveries

People who carry too many things mix useful and useless

things. Shuffling through useless papers co 1nd what is important

is a waste. Clearly, these people have failed to implement

Organization and Orderliness in their minds. In the same way,

sloppy thinking results in sloppy actions.

The same holds true in the factory Factories that lack

thorough 5S implementation tend to produce defects no matter what

they do to prevent them. Deadlines whiz by while everyone is busy

reworking defective products. It is indeed hard to meet delivery

deadlines in the face of problems like wasteful motion and too

many errors and defects.

When errors and defects are eliminated, deliveries

can go out on time.We need good work environments and smooth, highly

visible operations.Absenteeism is lower at 5S workshops.

Work is more efficient in waste-free

workshops.

Benefit 5. Zero Injuries Promote

Safely

Injuries can be expected when items are left protruding

into walkways, when stock is piled high in storage areas, or when

equipment is covered with grime, swan, or oil.

Other common events at factories that fail to implement

the 5S"s include confusion due to a lack of outlined storage

sites, head-on collisions when forklifts turn corners without

warning, hand injuries when operators attempt to fix stalled

equipment without cutting the power first, injuries when tall

stacks of inventory fall over unexpectedly, head injuries when

crane hoist handlers forget to wear helmets, and hand injuries

when press operators forget o press the safety switch before

handling the press. "Safety First" is a goodconcept — once

the 5S"s are in place.

We can discover mechanical failures and hazards

immediately when equipment is kept in spotless

condition.Maintain well-defined places to put things, plenty

of uncluttered aisles, and rest areas.Place things in a safe manner to prevent breakage,

etc.Clearly mark fire-extinguishing equipment and

emergency exits in case of fires, earthquakes, or other

emergencies.

Benefit 6. Zero Breakdowns Bring Better

Maintenance

Equipment should be routinely wiped and polished. Its

condition should be evaluated as part of regular daily upkeep.

When daily maintenance tasks are integrated w2th daily cleaning

tasks, equipment will be ready for use and result in an improved

"availability" ratio.

Trash, dirt, and dust can lead to major equipment

breakdowns and shorter equipment life.It is easier to see how equipment is running when

the workshop is free of shavings, filings, and oil

leaks.Nip breakdowns in the bud by maintain and checking

the equipment daily.

Benefit 7. Zero Complaints Bring Greater Confidence

and Trust

Factories chat practice the 5S"s arc virtually free of

defects and delays. This means they are also free of customer

complaints about product quality.

Products from a neat and clean workshop are

defect-free.Products from a near and dean workshop cost less to

make. Products from a neat and dean workshop arrive on

time.Products from a neat arid clean workshop are

safe.

Benefit 8. Zero Red Ink Brings Corporate

Growth

Companies cannot grow without the trust of customers.

The 5S"s provide a strong, solid base upon which to build

successful business activities.

People from 5S workplaces gain the respect and trust

of their communities.Customers are happy to buy from manufacturers that

have eliminated waste, injuries, breakdowns, and

defects.Factories with a solid 5S foundation arc more likely

to grow.

Reference

Fabrizio A., T., & Tapping, D. (2006 ). 5S for

the Office: Organizing the Workplace to Eliminate Waste. New

York, United State of America: Productivity Press.

Hirano, H. (1995). 5 Pillars of the Visual

Workplace: The Sourcebook for 5S Implementation. New York,

United State of America: Productivity Press.

Ho, S. (1999). Operations and Quality

Management. London: Cengage Learning EMEA.

Autor:

Jorge Salas Turrubiates

Estudiante